Full Article Written by Joseph Carbonara of Foodservice Equipment & Supplies Magazine

Finding ways to add or enhance foodservice offerings without stretching an operator’s already-thin labor pool represents a challenge that spans most segments.

This is why many feel the time may be right for the foodservice industry to finally begin adopting more forms of robotics and automation. That’s what Doctors Hospital did, and the Columbus, Ohio-based healthcare operation really saw sales and customer engagement start to percolate. That’s because in February of 2022, Doctors Hospital installed a fully automated coffee bar {Robojo}.

Doctors Hospital is the third largest facility in OhioHealth’s system, which serves 47 counties in the Buckeye State, going as far north as Cleveland and as far south as Athens. Some facilities in the OhioHealth system had nationally branded coffee concepts on their campuses, while others developed their own coffee concepts. This comes in addition to the complimentary coffee that was available to associates working at Doctors Hospital. And OhioHealth was looking to upgrade its coffee service at Doctors Health to take it beyond the complimentary coffee served on the various floors.

“How can we provide the service our associates are looking for without a big impact on labor?” says Heather Buck, senior director of food and nutrition services for OhioHealth. “We were looking for ways to thread the needle and we started to look for automated solutions.” The idea of implementing an automated solution was not a foreign one to Doctors Hospital. In fact, it had previously added an automated frozen yogurt machine that is a big hit.

Still, whatever solution Doctors Hospital would implement had to provide more than a good cup of joe. It also had to be equitable to those working the hospital’s second and third shifts, where it is notoriously challenging to provide good foodservice for various reasons. Plus, the solution had to support OhioHealth’s sustainability objectives. Finally, the solution had to be able to address fluctuating customer traffic on campus due to COVID-19 and other issues.

The automated coffee solution checks all those boxes and more, according to Buck. “This piece really did a lot for our associates as well as the community. As people start returning for care and other reasons, they see this in the lobby,” she says. “We have coffee shops at our other facilities and staff often ask why can’t these operations be open for a second or third shift? This allows us to provide an equitable answer seamlessly for 23.5 hours a day.”

The system at Doctors Health can make up to 250 different types of coffee-based drinks, including iced coffee. “Everyone has seen a coffee vending machine from the 1970s, and we still have those, but you also know you are not getting the coffee experience you want. With this, you are getting a European coffee experience in 60 seconds.”

Guests place their orders via smartphone app or by using a kiosk in the lobby. The system can make up to 100 drinks per hour, which is the same as 4 baristas, Buck says. But she’s quick to point out this new automated coffee operation did not come at the expense of anyone’s job. “We have not had a full staff at OhioHealth in the three years I have been there. So, this does not replace anyone’s job, but it does provide a lot of output. We are always open to having people come to work in food and nutrition,” she says.

In terms of sustainability, the system uses its own proprietary cups made from sugar cane and lined with bamboo. The cups are compostable; the robotic arm is calibrated to specifically pick up only one cup at a time, thus reducing waste. OhioHealth was allowed to select its own coffee roaster and chose a female-led business from the area. And Ohio Health is able to compost the spent coffee grounds. “One of our board goals is to be a community-driven partner based in sustainability. Working with a partner that’s like-minded was really important,” Buck says.

In addition, the automated coffee bar {Robojo} uses 40% less electricity than the nationally branded operations at OhioHealth’s other locations. “There’s a lot of good stories behind this,” Buck says. “The safety components in this machine are second to none. It does not over-steam the milk and it keeps everything at the right temperature. Plus, it’s all electronically monitored. It’s been easy for us to use and feel good about the safety of it, too.”

With respect to daily maintenance, that’s pretty straightforward. It takes about 30 minutes a day to restock cups, coffee, etc., and clean the system, per Buck. “It’s very low labor impact and very high yield.”

Calculating the return on an investment of this kind compared to other options is important. For example, there’s cost associated with building an on-premises coffee concept, be it a national or proprietary brand, Buck points out. What’s important is keeping the operation’s priorities in focus. “There are costs in all of the other things we do, as well,” Buck says. “The patient will always be number one and the center of what we do. That means at times we will have areas we may have to close certain things to serve those patients. This can remain in operation, regardless. As the world is changing, this system remains very safe. We just have to keep it clean.”

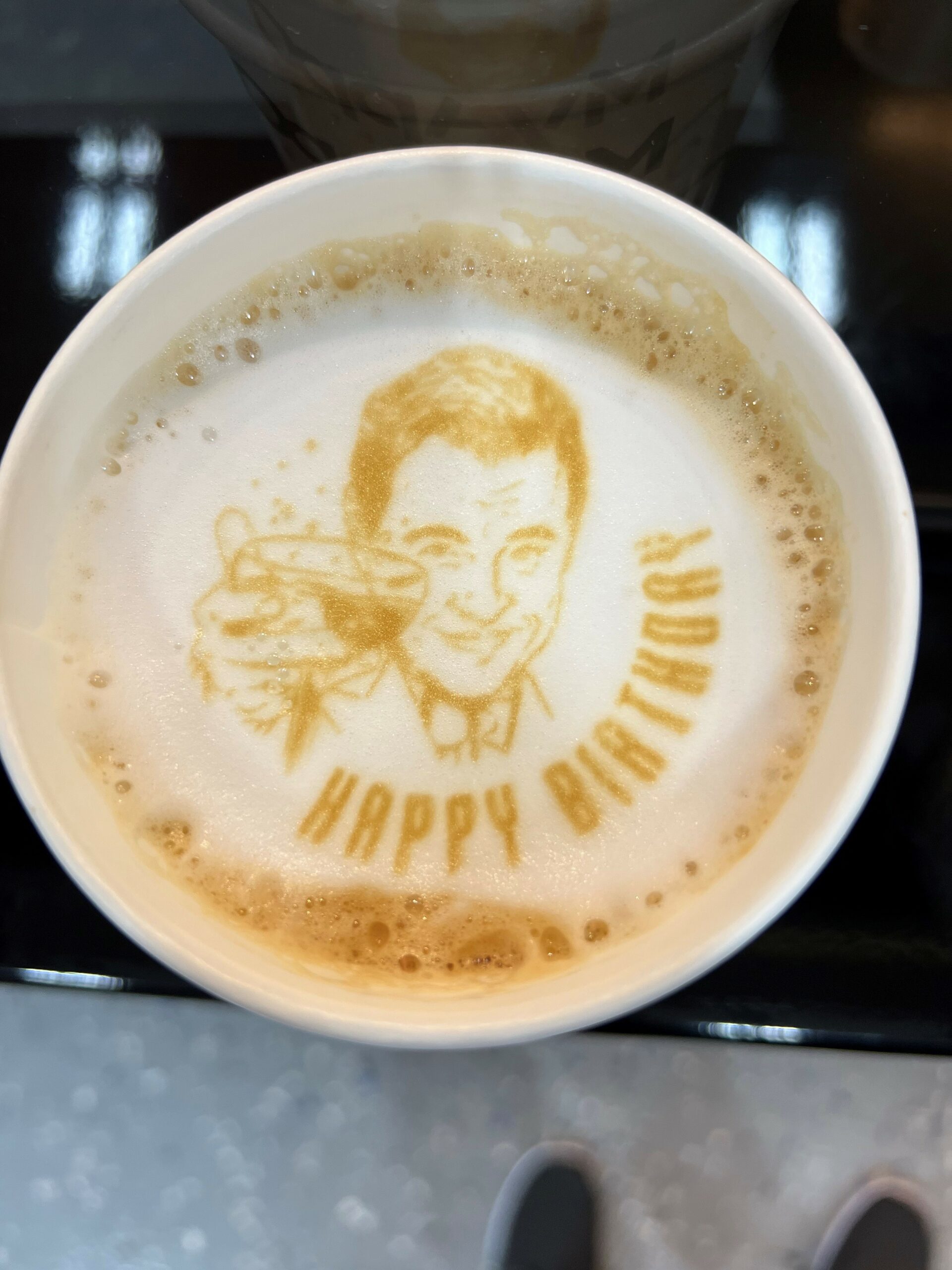

In addition to the high yield, the automated coffee bar has generated some strong engagement not only from the OhioHealth staff but from guests as well. People will post videos of the machine in action and snapshots of themselves to their social media accounts, Buck says. Plus, customers can download a picture of their choice and the machine will create that picture into the foam of the coffee drink you order. There’s even the ability to have a message like “happy birthday” added to the foam.

“It’s been a long couple of years for healthcare. And to have people smiling and laughing about having a picture of their dog in the foam of their drink, that’s a joy to be around. Our older visitors get a kick out of it and even send pictures to their grandchildren,” Buck says. “As this went viral in our own network, my phone had a lot of activity from people asking how they can get one installed at their location.”

While pleased with the initial rollout of the automated coffee bar, Buck is looking toward the future, too. “We are still working through bugs, taking in feedback so as future units roll out, we are better prepared,” she says.

Recent Comments